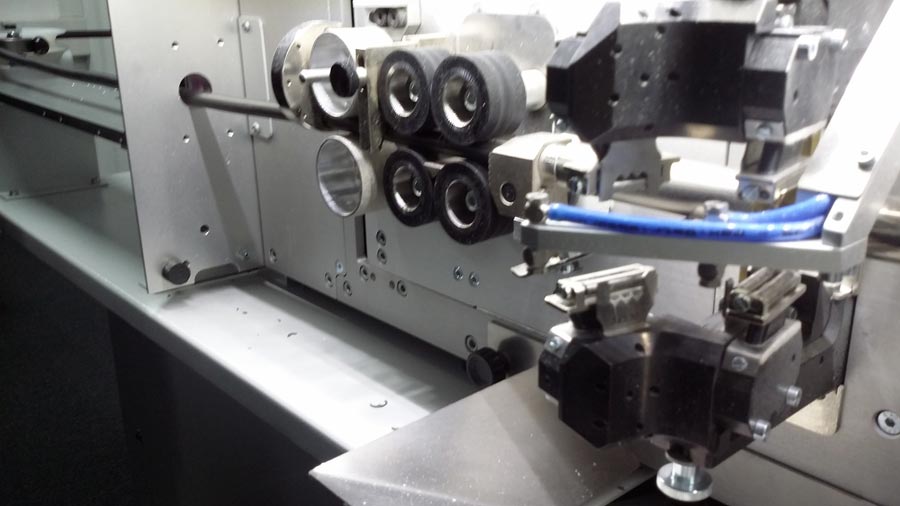

The continuous search for technological perfection, combined with a deep-rooted creative mentality typical of craftsmanship, have allowed the company to increase its processing standards by reducing production times and increasing the quality of workmanship. The products and production processes are constantly checked to be adapted to the regulations and standards dictated by companies of international importance. The verification of the final product, carried out as a sample or on all the pieces, consecrates the conformity imposed by the client.

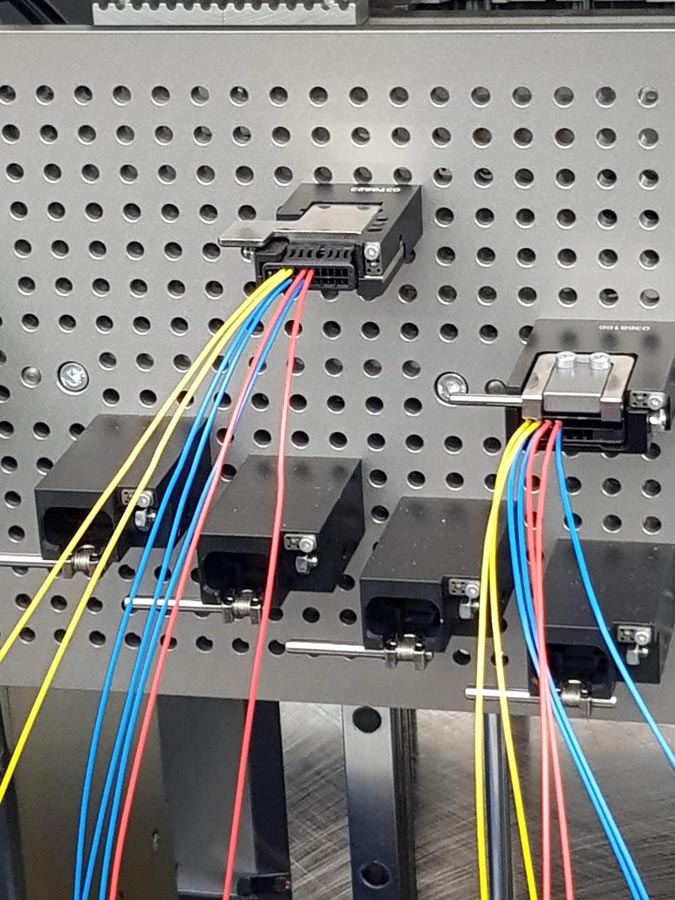

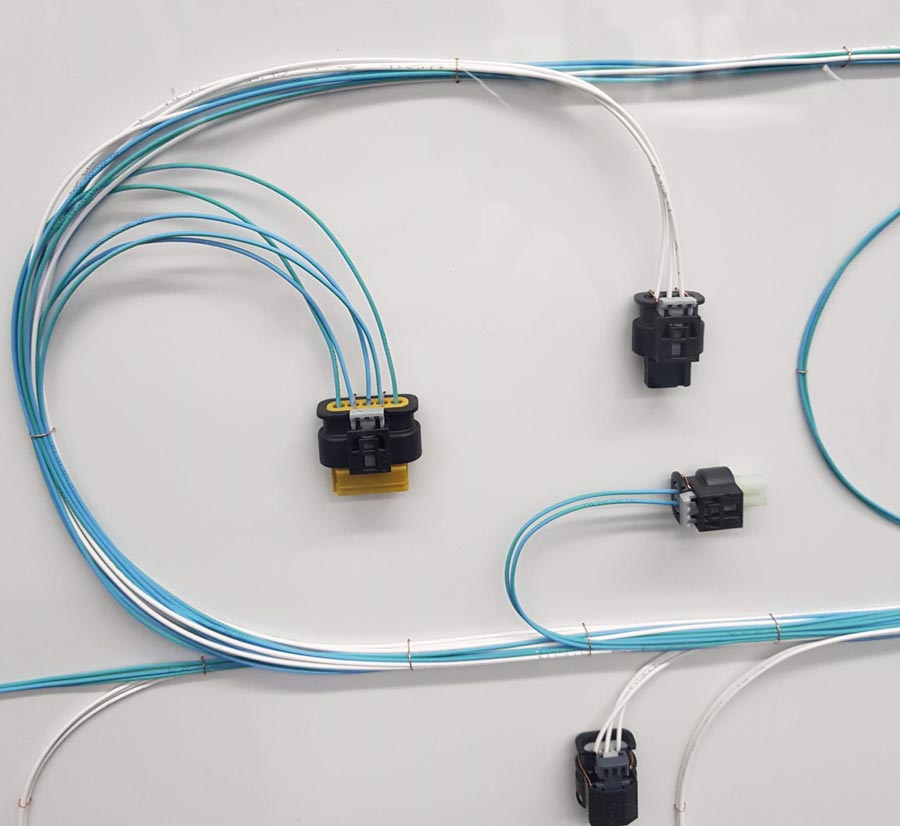

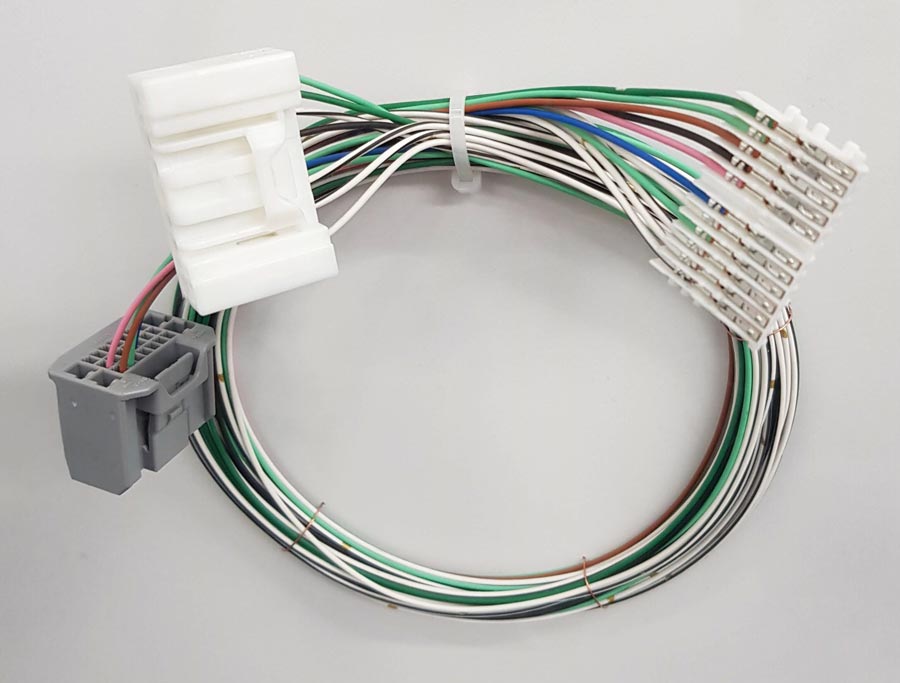

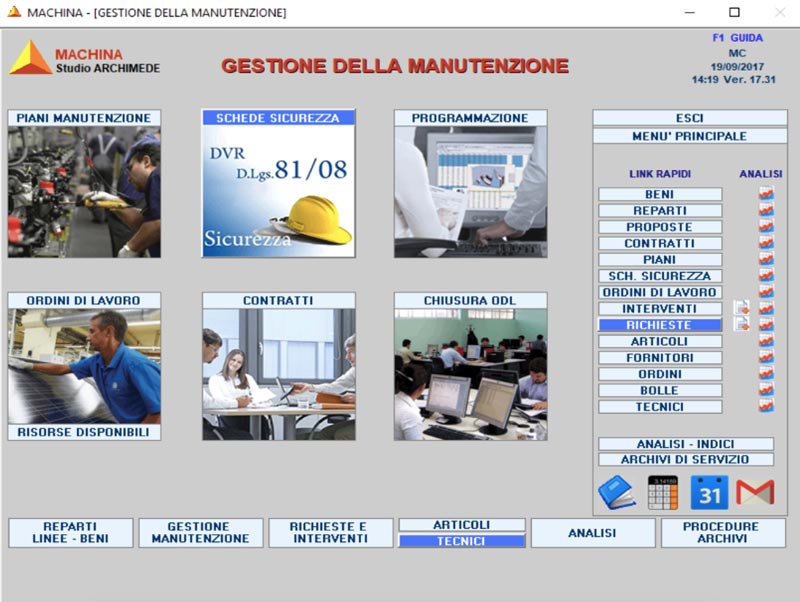

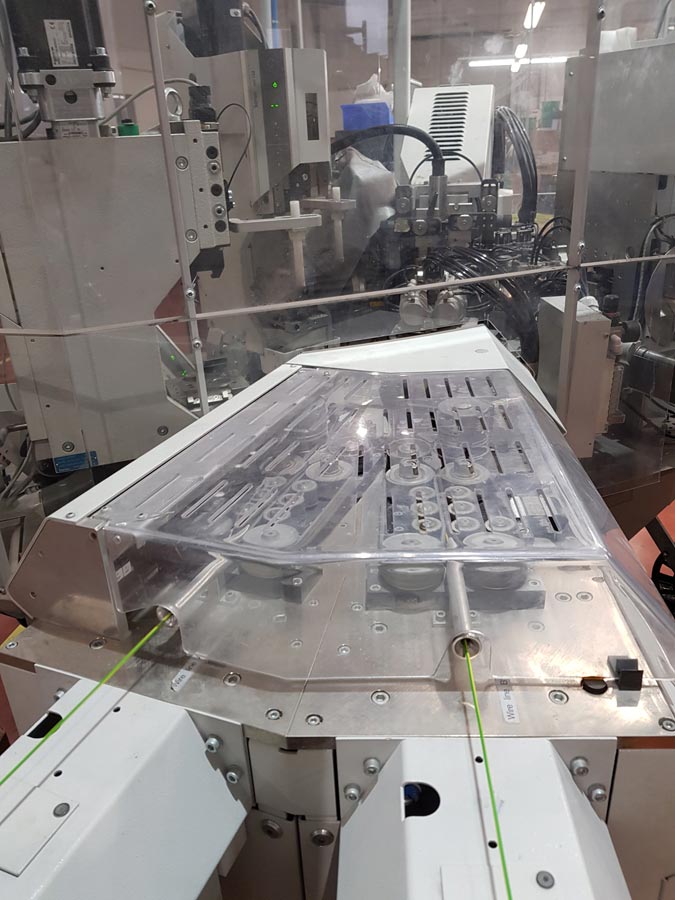

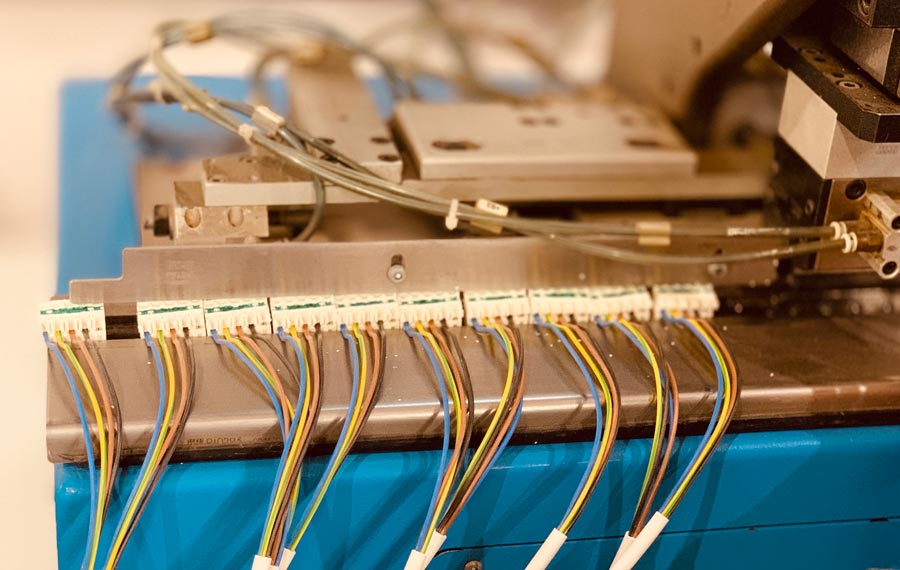

Montecavi is aware that cables, connectors and wiring harnesses are critical components and can not allow failures and malfunctions to arise. Along the production process, numerous quality control checks are performed by qualified and loyalized company personnel. Various methods have been developed to ensure product testing and ensure stability in the process control system: wiring harnesses checkouts and continuity tests with network connection and certified certificate reporting, dedicated online reporting systems for traceability, dedicated software for the management of maintenance cycles, online factory data acquisition and advanced artificial vision systems.

Ultimately, the key of Montecavi’s success is the ability to work flexibly and efficiently.

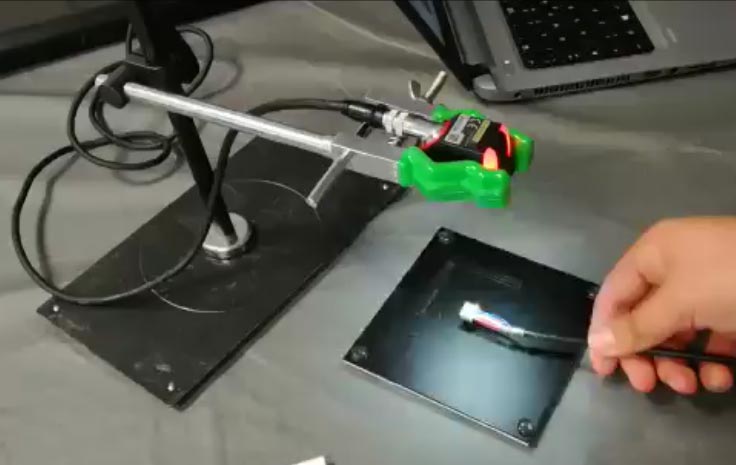

100% FUNCTIONAL TESTS ARE PERFORMED ON ELECTRICAL AND ELECTRONIC COMPONENTS OF ANY TYPE (AUDIO JACKS, TOUCH SCREEN DISPLAYS, INDICATORS, THERMOSTATS, LEDS, FANS, INDUCTORS, LAN/ETHERNET CONNECTIONS, ELECTRONIC BOARDS, LOUDSPEAKERS...). SPECIFIC COUNTERPARTS AND CUSTOMIZED DEVICES ARE CAREFULLY DEVELOPED BY OUR TECHNICAL DEPARTMENTS.

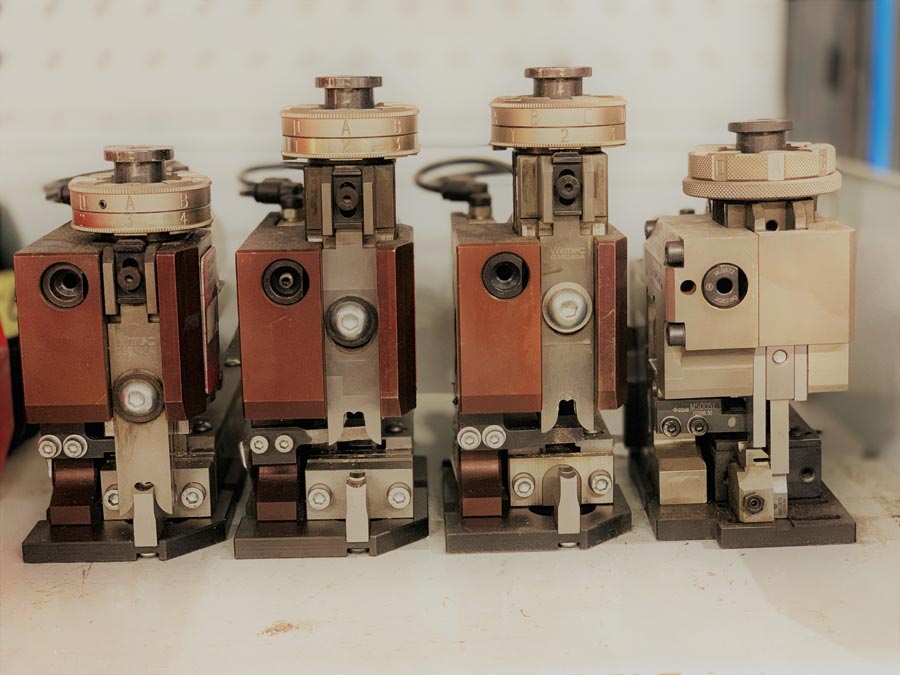

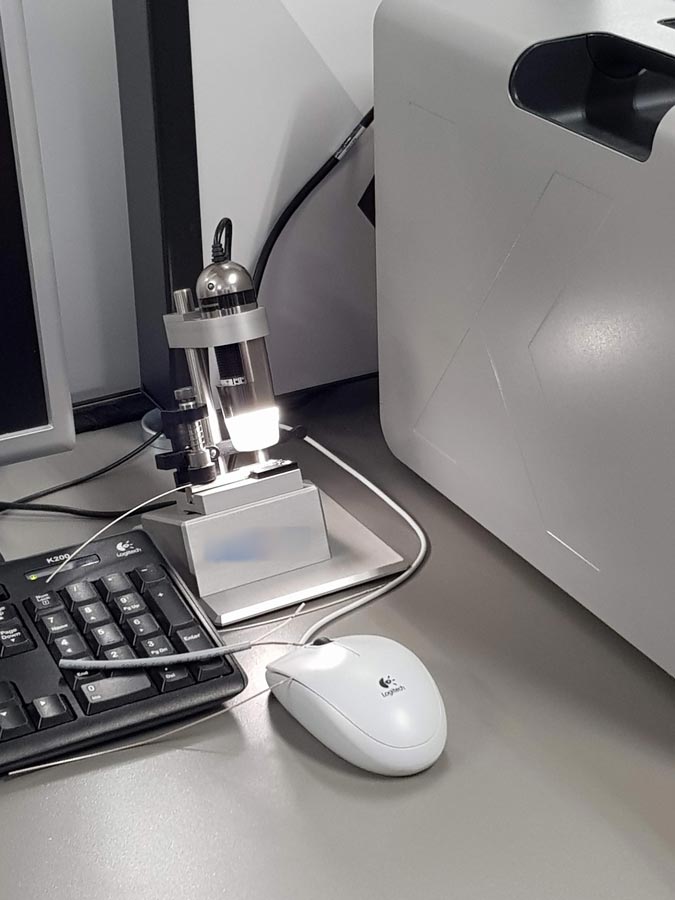

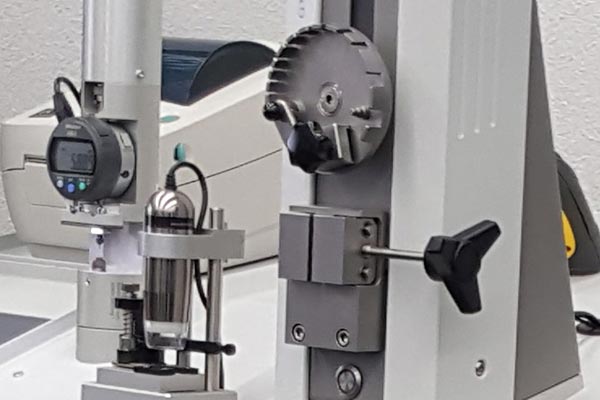

The research, development, design and process phases are controlled in the laboratory with a wide range of instruments to perform, e.g.:

- “Pull and Hold” methods for testing the loop tensile strength of cable ties;

- Microscopic analysis of the crimping processes;

- Traceability of the quality data from one database knowledge source;

- Process Capability;

- Process FMEA;

- etc.

After all, the full automation of the production processes, complete with integrated quality monitoring, is the best way to assure maximum quality and efficiency.

Further elements ensuring a constantly high quality service are:

- The marked degree of Lean flexibility of the processes, real and not only declared;

- System control, supported by identification and registration methods and procedures that allow immediate traceability of each product and event;

- Consistent machine data management;

- Short lead times in production;

- Guaranteed, documented quality;

- Global traceability;

- The proper management of stocks by means of six automatic vertical warehouses. These also allow precise and controlled picking of items for production;

- An assortment of materials optimised to meet all urgent needs;

- Control over material flows in every production phase.

DNV CERTIFICATION

The constant commitment and attention to high quality are demonstrated by the certifications obtained since ancient times. The first acknowledgement in fact arrives in 1996, the certification UNI EN ISO 9002:1994 for the Quality System with DNV, result of a hard work to reach the qualitative standards more and more demanded from the market. In 2002, Montecavi obtained the UNI EN ISO 9001:2000 certification. In 2016, it was one of the first companies to comply with the UNI EN ISO 9001:2015 certification. The history of obtaining the certifications is for Montecavi the demonstration and the natural legitimacy of an excellence and a belief that bear witness to a strong conscience for 100% quality on all types of harness.See online certification

UL CERTIFICATION

In 2011, the certification of product quality UL, file E344159, was granted to Montecavi. This certification is essential in order to be able to penetrate the American market , pursuing the objectives of expanding its market share and its turnover.See online certification